Why damaged starch is a must parameter in flour specifications for bakers

August 21, 2023

By Dr. M. Hikmet Boyacioglu

The term “damaged starch” is often perceived negatively by the baking industry. Many bakers view damaged starch as a flour quality parameter that “damages” product quality. However, damaged starch content in flour provides beneficial effects to help bakers produce top-quality products.

Damaged starch is the structural disruption/modification of starch granules in wheat and flour. The level of damaged starch in flour depends not only on the hardness of the wheat but also on the setting of the milling rolls. The miller can develop flour with varying water-absorption characteristics by adjusting roll settings to produce more or less damaged starch.

Why should bakers measure damaged starch?

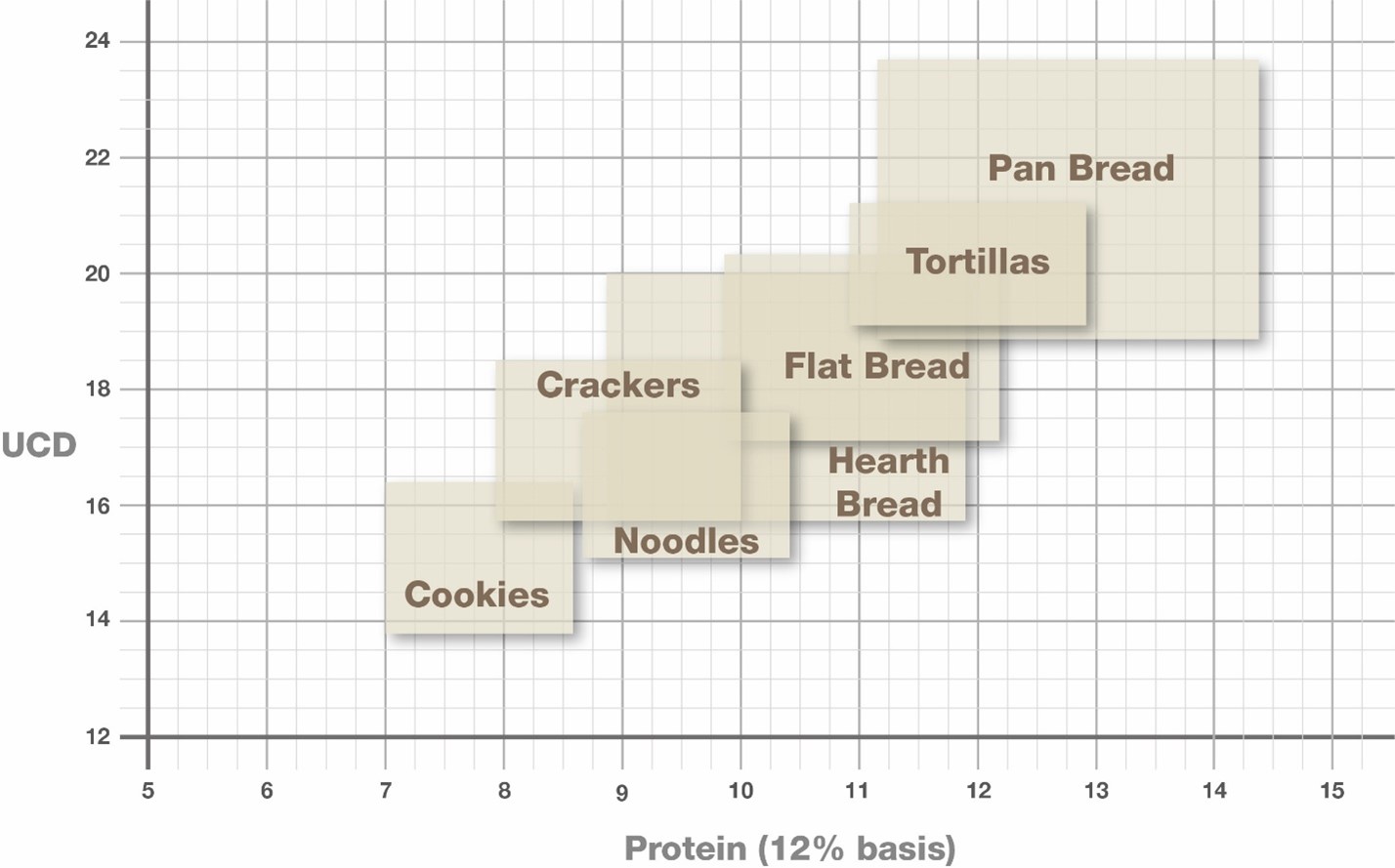

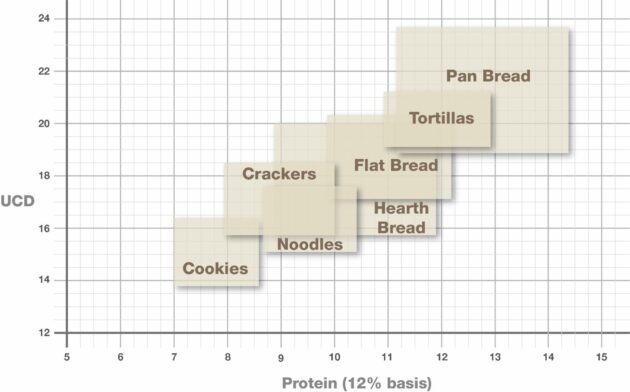

As shown in Fig. 1, when damaged starch occurs at optimal levels of the total wheat starch, they benefit flour performance for any baked product. Damaged starch is readily accessible to water and enzyme penetration, increasing flour absorption and providing fermentable maltose for the yeast.

Fig. 1: Approximate levels of damaged starch (UCD) to produce specific types of baked products.

KPM Analytics

Because damaged starch increases the initial water absorption of flour, doughs produced with a higher damaged starch content may not completely develop at the peak mixing time or may result in an excessively sticky dough. Likewise, too little damaged starch to produce a particular product may lead to production issues or a non-ideal fermentation process, leading to a final product not of proper volume, texture, or colour. Even after production, damaged starch can influence bread staling due to the retrogradation of amylopectin and crumb firmness.

How is damaged starch measured?

Given the importance of damaged starch in the flour and baking industries, many internationally recognized methods exist to quantify its presence. One such method is the Amperometric Method (AACC Method 76-33.01), which measures the kinetics of iodine absorption in a liquid suspension using an amperometric probe. The Amperometric Method is specific to white flour obtained from Triticum aestivum from laboratory or industrial milling. Still, it is also used for whole wheat flour.

However, despite its benefits to both the miller and baker, manually conducting the Amperometric Method is time-consuming.

The SDmatic from KPM Analytics is an automated damaged starch analyzer recognized by several international standards (NF, AACC, ICC, FTWG, ISO). Photo: KPM Analytics

For this reason, CHOPIN Technologies – now a member of the KPM Analytics family of brands – developed the SDmatic automated starch damage analyzer. SDmatic performs the Amperometric Method (Medcalf & Gilles, 1965) to exact international standards and presents accurate damaged starch data in less than 10 minutes.

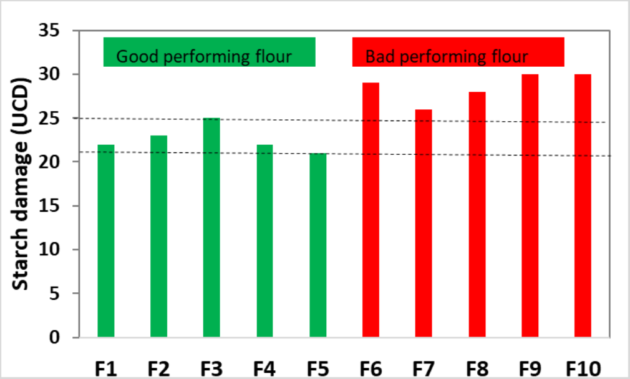

Case Study: Checking the regularity of damaged starch of incoming flours

In this example, a bakery launching its first organic bread product faced fluctuations in the quality of its finished product (collapsing, poor volume, off-colour, etc.) despite their millers supplying flour at exact protein specifications (between 13-13.5 per cent). Because of their organic/clean-label promise to consumers, using additives and improvers could not be possible.

The bakery analyzed 10 different flour deliveries with near-equal protein levels in their testing lab in small-batch baking tests. The baking tests yielded five flours that developed an ideal product, while the other five developed a product outside specifications.

Fig. 2: While the 10 flour varieties each had similar protein levels (13-13.5 per cent), after testing each flour with the SDmatic, the bakery saw an imbalance of damaged starch in the flour, presenting production issues. Diagram: KPM Analytics

As shown in Fig. 2, with KPM Analytics and the SDmatic, the baker assessed the starch damage of each of the 10 flour samples. Surprisingly, they learned that the five flour samples that produced the out-of-spec product had starch damage (UCD) count above 25, while the good-performing flours were between 21-25 UCD.

While protein content is a vital flour quality parameter, as this case indicated, damaged starch content significantly affected the final product outcome.

Prioritizing damaged starch analysis equals fewer production issues, better quality products, and happier customers

From a miller’s standpoint, their objective is to produce the most flour from their wheat and at specifications requested by their baker customers.

From a baker’s standpoint, their goal is to maximize the water absorption content of their flour to improve their yield and generate a return on their flour investment.

Analyzing and balancing damaged starch content in flour is essential for both parties to meet their objectives.

Using automated technologies like the SDmatic allows both millers and bakers to control damaged starch and improve the consistency of their flour and products with ease.

Dr. M. Hikmet Boyacioglu is a cereal scientist and applications development specialist at KPM Analytics.

Dr. M. Hikmet Boyacioglu is a cereal scientist and applications development specialist at KPM Analytics.

Print this page