Mecatherm industrial system produces hybrid of classic and artisan-style baguette

January 26, 2022

By Bakers Journal

Photo: Mecatherm

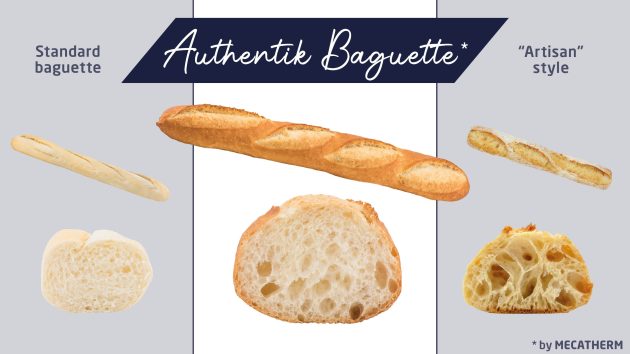

Photo: MecathermMecatherm has launched the Authentik Baguette, a recipe and industrial system that allows manufacturers to offer a product positioned midway between the classic baguette and the artisan-style baguette.

The company says there is a demand for a product that can meet the requirements of both consumers (a quality product, natural ingredients, and an affordable price) and distributors (simple to prepare and use for snacks, extended shelf life, and controlled quality).

Mecatherm developed a new recipe for industrial baguettes: a baguette combining the advantages of the classic baguette and the artisan-style baguette, suitable for industrial production, and allowing industrial bakeries to easily upgrade their production lines while maintaining a profitable business model.

The Authentik Baguette is a natural product made from basic ingredients: water, flour, salt, yeast and vitamin C. Its hydration rate, which is almost five to 10 per cent higher than that of the classic baguette, makes it possible to produce a product that is fully baked in the factory before freezing. This has the major advantage of a warming time reduced to three minutes at the sales point, compared to a bake-off of 10 to 15 minutes for a classic parbaked baguette. Distributors can therefore be much more responsive when refilling their shelves, avoiding waste and offering products with a uniform bake and colour because they are produced entirely in the factory.

Graphic: Mecatherm

The Authentik Baguette is a gourmet product with a golden crust combining crispiness and melting crumb, while remaining easy to eat and suitable for sandwiches. With a more hydrated dough, the Authentik Baguette has a shelf life twice as long as a classic baguette.

For manufacturers, the Authentik Baguette has numerous advantages, starting with the cost price which, given the basic ingredients of the recipe, is lower than that of a classic baguette. On the other hand, the limited investment and time required to upgrade a classic production line to an Authentik Baguette production line ensures rapid time to market and an optimal return on investment. It is also a good way to upgrade existing production lines for products that are losing momentum and produce a finished product that is differentiating and has high added value.

To address the challenges of working with a hydrated and rested dough, the company has designed equipment improvements that can be easily integrated into existing operational production lines.

Three stages of the Baguette Authentik manufacturing process require special attention and modifications to be made on a production line for classic baguettes: kneading, dividing, and baking. These stages require a kneading carousel to manage additional resting times, an M-NS divider to process hydrated dough and an additional vertical oven module to ensure a full bake.

“Industrial baking is changing. Consumer expectations are evolving towards more diversity but also higher quality products, made with more natural ingredients,” said Olivier Sergent, president of Mecatherm. “We are convinced that this innovative solution will enable our customers to better meet new market expectations, without compromising their industrial performance, while integrating the new challenges related to sustainable development.”

Mecatherm designs, produces and installs equipment (make-up lines, ovens, coolers, freezers) and automatic production lines for customers in the bakery and pastry sector. The company, founded in 1964, has two production facilities in France as well as sales offices in France and the United States.

Print this page