Kason unveils new mill

October 23, 2018

By Bakers Journal

Image courtesy of Kason Corporation

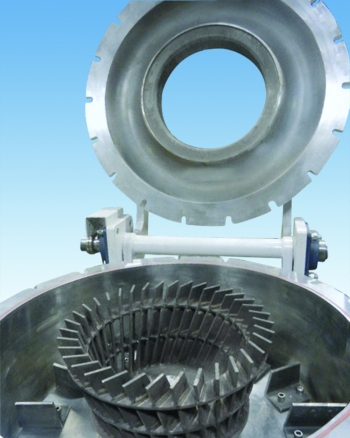

Image courtesy of Kason CorporationKason Corporation has introduced a new Air Classifier Mill with higher capacity than any model previously offered by the company.

Model CAM 1300 combines impact grinding and air classification in one machine to produce fine grinds with narrow particle size at rates to 16.5 tons (15 tonnes) per hour for large-scale processes.

Intended for bulk foods, pharmaceuticals, grains and mixes, the mill allows control of the air flow rate and grinding temperature to condition heat-sensitive or hygroscopic materials.

Material enters the milling chamber where a spinning rotor impacts the particles against grinding segments inside of the chamber wall by centrifugal force. A rising column of air lifts the particles into the rotating classifier wheel, separating on-size material and directing it to the process air stream for collection or further processing. Over-size material returns by gravity into the path of the spinning rotor for further grinding.

Particle size is readily controlled by varying the rotor speed, classifier speed, airflow rate and feed rate, eliminating the need for separate classification equipment.

The easy-clean design includes a “clam shell” style lid that, when fully opened, provides complete interior access for change-outs of grinding media and sanitizing to prevent cross-contamination.

It is available in carbon steel or in 304 or 316 stainless steel finished to industrial or sanitary standards. Hastelloy® and other alloys are also available for processing of corrosive or abrasive materials.

Print this page

Leave a Reply