Food Safety In The Spotlight

November 13, 2008

By Clíona M. Reeves

Food safety stories are never absent in the news these days. From updates about the Maple Leaf listeria crisis and resulting deaths, to overseas stories about melamine in dairy products manufactured in China, to Cadbury’s late September recall in Asia and Australia, we are constantly reminded how interconnected our food supply is.

|

| Baked goods made with eggs risk contamination from microbes if internal temperature is not sufficient. |

|

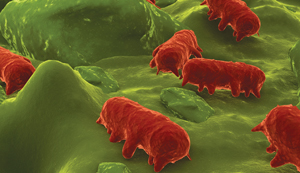

| Salmonella virus |

Food safety stories are never absent in the news these days. From updates about the Maple Leaf listeria crisis and resulting deaths, to overseas stories about melamine in dairy products manufactured in China, to Cadbury’s late September recall in Asia and Australia, we are constantly reminded how interconnected our food supply is.

But neither of these examples has anything to do with the baking industry, so bakeries and their suppliers need not worry, right?

Nope. Not by a long shot.

“The challenges are real,” says Paul Medeiros, manager of consulting services at the Guelph Food Technology Centre, a training and consulting firm in Guelph, Ont., “and it doesn’t help that margins are tight, which can constrain resources and time to deal proactively with food safety. But misconceptions are even more dangerous. Commonly, people assume that any microbes will be killed in the heat of baking, but microbes are not the only threat, and bread is not a bakery’s only product. Products with fillings or icings – custards, for example – may look fine when baked, but may not have reached sufficient internal temperature to kill microbes, such as salmonella, lurking in the egg. Likewise, there are additional threats from physical hazards, such as glass fragments, or chemical hazards, such as contaminants in ingredients. For example, do you know your supplier well enough to be sure that the whey powder you just received does not contain melamine?”

Dealing effectively with suppliers is an art in itself. Simply assuming that ingredients are safe is a dangerous gamble. “You may not be buying your ingredients from the manufacturer, but rather from a broker, who may have minimal or even non-existent knowledge of food safety,” Medeiros says. “And even if you’re buying directly from a manufacturer, they may have combined raw ingredients from multiple sources to prepare your order.”

Beyond the headline-grabbers of listeria and salmonella lurks the equally deadly realm of food allergens.

“Allergens are a major challenge for the baking industry because the ingredients we use come from every category of 10 priority allergens the Canadian Food Inspection Agency (CFIA) has identified,” says Paul Hetherington, CEO of the Baking Association of Canada. “Wheat, dairy and egg are regularly used, and often soy, nuts and other serious allergens are major ingredients as well. As a result, it is vital that bakery operations ensure that their products are properly labelled to declare intentionally added allergens, such as nuts, that they alert consumers that a product may contain other unintended allergens, and that they make every effort to prevent cross-contamination.”

More easily said than done. “We did a paper for CFIA on the ability of sesame seeds to migrate through a plant, from pre-production, to baking, to cooling,” Hetherington says. “The structure of allergens makes them very difficult to keep out, but precautionary statements are no substitute for good manufacturing practices.”

Medeiros agrees, cautioning that “adding ‘may contain’ statements to a label is not a get-out-of-jail-free card. CFIA evaluates all issues on a case-by-case basis and may ask for a recall anyway.”

Battle plan for food safety

So what is a bakery operator to do? There are many steps they can take, but there are two overriding concerns.

“First,” says Medeiros, “you must have the solid, unwavering commitment from management to provide adequate staffing and resources to achieve food safety objectives. And the system must be just that, a system which everyone follows, not just a project dumped on the HACCP co-ordinator, and dependent on whether his boss is around to breathe down his neck every day. The system must be shared across the organization, and must be robust enough to survive staffing changes. In fact, it should be a co-ordinated effort through the entire value chain, going beyond employees and management to include suppliers and distributors.”

What should this system consist of? “You need good manufacturing practices (GMPs) to ensure a safe manufacturing environment, such as ensuring proper sanitiation and ventilation,” Medeiros says. “Then HACCP, or Hazard Analysis Critical Control Points, identifies potential areas in the manufacturing process where hazards could arise and builds safeguards in to prevent them, and to alert operators that something has gone wrong. Allergen control programs are needed to prevent cross-contamination during manufacturing. And finally, supplier quality assurance programs are needed to ensure that the ingredients you receive are safe. After all, if your product is compromised by contaminated ingredients, it is still your customers who are at risk, and your brand which can be damaged.”

A good traceability plan is another essential. No one wants a recall, but it is vital to be able to track and backtrack ingredients, and to follow each batch of product leaving your facility, enabling you to recall it voluntarily before it reaches consumers and causes illness – or worse!

Say what you do, do what you say – and prove it

Having a great plan is only the beginning. Now you have to implement it and document it. Without clear documentation, you have no way of knowing whether you are actually achieving what you laid out in your plan. Unless you record equipment maintenance and cleaning, temperatures in storage areas, and other important measures, you will not be able to demonstrate the safety of your product – or to backtrack a problem to its source, and correct it.

People power

The heart of a reliable food safety plan is the HACCP team, a group of people from each department, including the plant floor, each of whom brings a unique awareness of a different part of the environment and process. No one knows the manufacturing line as intimately as the people who work with the equipment, day in and day out, and they can point out problems that might never have occurred to others in the company.

In addition, training for everyone is – or should be – a central pillar in a good food safety plan. Everyone, not just the HACCP team, is responsible for the safety and quality of the products they manufacture. This is a team effort, and if anyone drops the ball, everyone can be hurt. The organization must train its people, and the employees themselves must apply that training in their work, helping each other to ensure that the rigorous procedures are carried out at all times. This can mean something as seemingly minor as reminding each other to wash hands thoroughly, or as large as spotting and reporting a problem with a piece of equipment.

The goal: consumers’ safety

The goal of all this hard work is to ensure that consumers can enjoy safe, healthful foods, and can rely on your brand as safe for their families. Food safety may not be as “sexy” as quality, novelty and convenience, but it is a non-negotiable starting point, as well as a legal and moral duty of everyone in the food industry.

“As food safety stories emerge in other sectors, consumers are becoming more aware of the issue generally, and are demanding more information about the products they buy,” Hetherington says.

The more this trend grows, the greater the opportunity for those who can make unimpeachable food safety an important part of their brand.

For more information:

• Baking Association of Canada: www.baking.ca

• Canadian Food Inspection Agency (CFIA): www.inspection.gc.ca,

• www.inspection.gc.ca/english/fssa/polstrat/haccp/haccpe.shtml

• Guelph Food Technology Centre: www.gftc.ca

Clíona M. Reeves, MA, is a freelance writer based in southern Ontario who has worked in communications in the food industry for the past 17 years.

Print this page

Leave a Reply