Tricks of the Trade: July 2012

July 5, 2012

By

FORMA-LAB

There are a multitude of bread improvers on the market, but you have to ensure you are using the right one for your production

There are a multitude of bread improvers on the market, but you have to ensure you are using the right one for your production. You can over-treat by using too much, or too many (two to three) different improvers.

It is necessary to first know the function of a specific improver to determine whether it is needed. Then it is necessary to look at the composition of ingredients to obtain the desired effects for your production needs.

|

The quantity to be used becomes important according to the following parameters:

- the concentration of improver (dosage suggested by the supplier)

- the fabrication method used (straight dough, sponge and dough, or no-time dough)

- the type of product (fresh, frozen dough, par-baked, etc.)

- the fermentation time (slow, fast or retarded process)

- the flour used (treated or not, important to verify the content of oxidant)

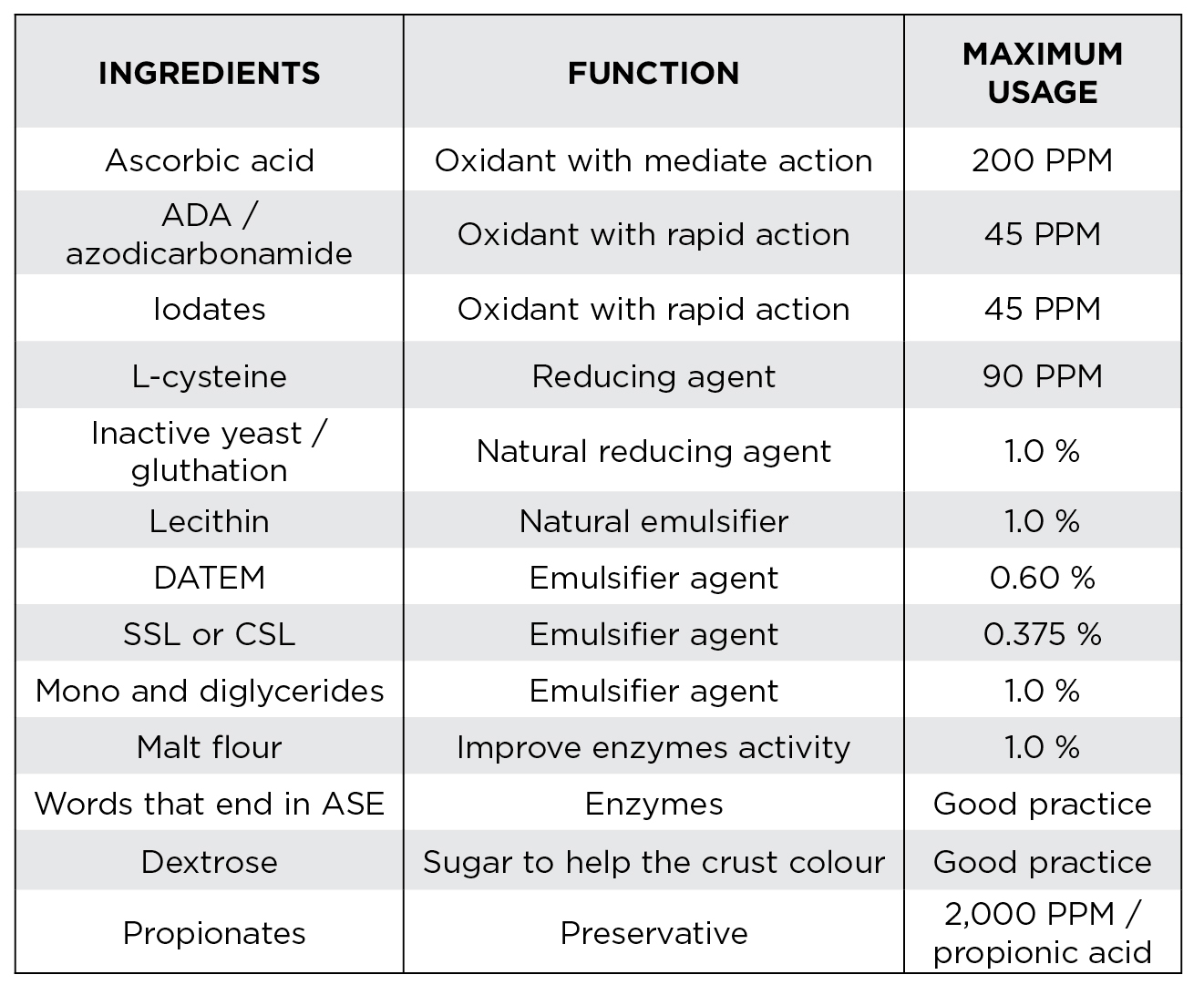

The complete improver contains oxidizers, reducing agents, emulsifiers and enzymes. The following ingredients can also be added: dextrose, salt, propionates and oil. Often, flour can be used and the dosage would vary from 0.5 to 3.0 per cent. The percentage of use is a recommendation of the supplier and may be reduced according to its need.

Usually the suggested maximum dosage, respects the maximal allowed standards while considering the addition for treated flour (rate of ascorbic acid and ADA).

For example, by using different methods, we could use same improver based in 3.0 per cent recommended use in the following way:

- no time dough for frozen products: maximum 3.0 per cent

- sponge and dough system: use 2.0 per cent

- straight dough with 90 minutes of rest: use 1.0 per cent

- retarded dough method: use 0.5 to 1.0 per cent

- dough made with pre-ferment or starter: use 0 to 0.5 per cent

- artisan bakers / craftsman: not recommended but tolerance would be at 0.25 per cent

The suggested percentage is always based on the weight of flour used.

Function of the components for improver:

The use of complete improver helps all the stages of the bread making:

- It helps the complete development of the gluten during mixing. (oxidants)

- It lubricates the dough and makes it more elastic. (emulsifiers)

- The alpha amylase cuts the starch to produce sugars. (enzymes)

- It brings the yeast to his maximum activity during fermentation. (oxidants)

- It helps to relax the dough during rapid process. (reducing agent)

- It affects the final volume by the quantity of CO2 loosened under the heat and the elasticity of the development during baking.

- It contributes to the Maillard effect (caramelizing of the non-use sugar by changing the colour of the crust). (dextrose)

- The emulsifiers delay the evaporation of the water and enzymes expand the shelf life.

Improver influences the following parameters:

- the structure of the crumb

- the softness of the crumb

- the crunchy of the crust

- the volume

- the shelf life

- the aroma and the taste

You should not look at the cost of improver by kilograms but by the use. The price will be more expensive on a concentrated improver but the final cost may be better. It is left to you to find the right improver for the performance and the tolerance you require in your product.

Mario Fortin is an international bakery consultant and owner of

FORMA-LAB, consulting services to Bakers and Suppliers. If you need

technical information, send your question to info @forma-lab.com.

Print this page

Leave a Reply