A Fresh batch

September 17, 2009

By James Careless

Fall means back to school and back to work. In the bakery equipment

industry, it means a time that manufacturers get back to unveiling new

products. Here are some to watch for:

|

|

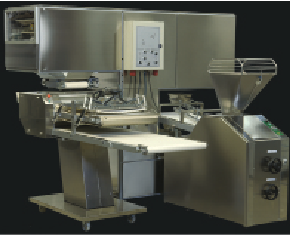

| Unifiller Systems has updated several of its automated depositors.

|

Fall means back to school and back to work. In the bakery equipment industry, it means a time that manufacturers get back to unveiling new products. Here are some to watch for:

Ashworth Bros.

www.ashworth.com

“Our new Omni-Pro Flex Lite (1.5-inch pitch) conveyor belt is a rugged, strong, lightweight belt for conveying heavy products in pans and trays,” says sales director Marty Tabaka. “With this new design, bakers can convey heavy loads without using a heavy, high-energy conveyor belt design.”

Meanwhile, the Omni-Pro 075 (3/4-inch pitch) stainless steel conveyor belt offers increased strength over similar models, Tabaka says. “The increased strength of the Omni-Pro comes from the 360-degree, button-less welds utilizing a ‘zero tension’ design, which allows a higher load bearing capacity.

Unlike a traditional bridge weld, [this] weld is free from surface imperfections and crevices, which improve hygienic characteristics by eliminating the possibility of bacteria entrapments.”

|

|

| Unifiller Systems has updated its Cake-O-Matic machine. | |

|

|

| MIWE’s new lift-in rack oven. | |

|

|

| Erika Record’s new Ciberpan Single Piston Divider.

|

|

Erika Record

www.erikarecord.com

Erika Record has unveiled the new Ciberpan Single Piston Divider, “a simple and economic way to produce up to 1,800 pieces per hour on a small footprint,” says general manager Max Oehler. “It has a huge weight range from two ounces to 21 ounces and, if necessary, can double up pieces and produce 900 pieces from four ounces to 42 ounces. This system can make any rolls or breads that are long in shape and can handle up to 75 per cent hydration. You can also hook up a rounder at the end of the proofer to make round products.”

Also, the Ciberpan Single Piston Divider can be equipped with a pre-rounder or a tunnel. Erika Record sells these in many different shapes and sizes, depending on available space and the resting time needed.

Megart Custom Bakery Solutions

www.megartsystems.com

It’s difficult for Megart Systems to talk about what’s new for fall, says international sales director Bruce Williamson. The reason: When it comes to bakery applications – including depositing equipment for fluid products and dry toppings, conveyors for moving baked goods, pans and boards, and packing equipment – “much of what we build is quite custom, so we are in essence always building ‘new’ equipment,” he explains.

One of Megart’s latest installations was a complete production line for phyllo pastry production. “The line included a depositor to apply a thin layer of melted butter on to the phyllo pastry strips, and a second depositor to measure the filling and place it onto the middle of the pastry strip,” Williamson says. “Included was a 20-foot conveyor where the pastry strips were folded into their final shapes.”

Mindful of the tough economy, Megart is trying to devise custom applications that offer improved technology and better productivity. “We continue to develop a line of depositors for retail bakeries and smaller wholesale shops. These depositors are less expensive, but still offer the robust quality which is typical of Megart equipment,” Williamson says.

MIWE

www.miwe.ca

MIWE’s new lift-in rack oven combines high-tech versatility with easy loading and fast installation. “The modern digital control system of the MIWE allows for intuitive operation and can store as many as 30 baking programs (each with up to five baking phases) that can be called up at the push of a button,” says MIWE Canada president Daniel Kroenert. “The MIWE air control allows bakers to determine precisely the exact amount of circulated air in the system, and thus to create ideal temperatures and atmospheres for a wide variety of baked goods. Last but not least, a process MIWE developed and called ‘gradient baking’ ensures automatically perfect baking results even when the oven is only partially filled.”

That covers versatility: “When it comes to loading the oven, the lifting device of the MIWE lift-in gives the baker a much-appreciated helping hand,” Kroenert says. “A special patent-pending mechanism lifts the rack into rotating position.” As for quick installation? Thanks to the MIWE lift-in oven’s modular design, “the MIWE lift-in can be fully installed on the customer’s premises within six to eight hours,” he continues. “The oven door can be hinged on the right or the left during setup, with absolutely no need for special tools. And since it can be built in on three sides, you can put it anywhere you want.”

Picard Ovens

www.picardovens.com

Picard has unveiled a new 32-pan Revolution Oven, which “lets you save up to 45 per cent on your energy bill,” says marketing co-ordinator Marie Lemay. Describing this unit as “the most compact oven of its category,” Lemay says it’s equipped with an inner ventilation system and revolving trays. In terms of versatility, “this oven can bake a wide variety of products at the same time, no matter how much time each one needs,” she tells us. “One major advantage of a Picard Oven is its self-generating steam system. With this technology you will obtain flavourful, quality products.”

One thing is certain: The 32-pan Revolution Oven has more capacity than Picard Ovens’ other such models, allowing bakers to make more kinds of products at the same time than before. “No longer are you bound by the limitations of the rack oven,” LeMay says.

Rea UltraVapor

www.ultravapor.com

Cleaning is a top priority for bakeries, especially when dealing with allergens that must be removed for product changeovers. This is where Rea’s UltraVapor steam-based cleaning/sanitization system comes in. Tests conducted by the Guelph Food Technology Centre measured before and after levels of common allergens on varied work surfaces, after a complete hot water rinse with a one-inch hose and then again after using UltraVapor equipment. They found that a water rinse resulted only in a one-log reduction in allergens, while UltraVapor achieved a further two-log reduction. GFTC concluded that a water rinse alone is insufficient to ensure food safety and that UltraVapor is particularly effective on hard-to-clean surfaces.

“Sanitarians and quality assurance managers love the deep cleaning capability of our equipment, particularly in areas that have been either very challenging, or even impossible, to clean adequately,” says Rea vice-president Trevor Moore. “They also find that the equipment removes allergens and spoilage organisms from processing equipment with less labour, less chemical, less water and with better results than traditional methods.”

Unifiller Systems

www.unifiller.com

Unifiller Systems’ automated depositors allow bakers to speed up the production and assembly of pies, cakes and other baked goods. For the fall season, “we have improved a few of our depositors like the Pro 1000 and the Universal 1000; they are now called the Pro 1000i and the Universal 1000 I,” says multimedia specialist Jamie Bobyk. “We have also improved our very popular Cake-O-Matic machine with Touch Screen Servo controls.”

The details: “The I series of depositors brings all the connections front and centre, making it easier for the user to connect, disconnect and clean,” Bobyk says. “The speed control is now a speed dial that allows the user to easily change the speed of the deposit with a simple turn to the left or right.”

Meanwhile, “The Touch Screen Servo controls for the Cake-O-Matic makes it very easy for the user to store recipes and fine tune their requirements,” he adds. “With servo controls, accuracy is much greater that with pneumatic controls.”

James Careless is an experienced freelance writer with credits at Canadian Grocer, Food in Canada and Western Grocer magazines.

Print this page

Leave a Reply